Manuka Suriyage

CFD analysis-based optimization of a microfluidic droplet generator

Precise control of droplet formation and droplet size control is critical in droplet microfluidic based applications. A three-dimensional cross flow, Co flow, Flow focusing and step emulsification type droplet generators are analysed through a CFD model to investigate the effect of design parameters for droplet formation. The droplet generators are active fluid velocity-based designs which are numerically studied in four different regimes such as squeezing, dripping, jetting and multi tip breaking. Mainly the dimensional parameters of the droplet generators, continuous and disperse phase flow velocities and the fluid wall conditions are analysed for water droplets formed in coconut oil. Droplet shapes and undesirable effects in droplet formation is expected to be studied in detail. The numerical study effectively provides the basic understanding regarding the characteristics and effect of dimensional and fluid parameters in microfluidic droplet formation through non-Newtonian fluids.

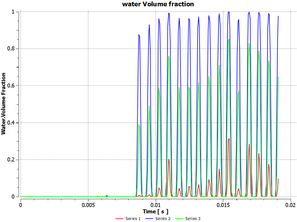

I am working on 8 different droplet generator geometries such as Cross-flow (T junction, double T junction, Double T droplet pair generator), Co-flow (quasi 2D planar), Flow-focusing (Axysimmetry, Planar) and premix membrane classification. The shape and the effect of the critical dimensional parameters and the effect of the phase velocities towards droplet size and droplet scheme is studied in detail based on simulation results. Moreover, the frequency of droplet generation is studied with respect to the fluid parameters. Some results for the T junction is illustrated in the following figures.

Apart from the dimensional and fluid velocity parameters, the influence of various rheological parameters, namely, power-law index, consistency index, and, interfacial tension are taken into consideration. I am currently working on the parametric studies of dimensional and velocity parameters.